Plant Resource Manager (PRM)

The PRM software centrally manages large amounts of status and maintenance information from automation and production assets. PRM has various maintenance support functions, including online functions for monitoring and diagnosing devices and equipment.

PRM Overview

Why it is important to have a proper asset management regime in place for reliable, efficient, and profitable plant operations

Damage to or failure of plant equipment can have a significant impact on operation of the plant as a whole. Yokogawa’s Plant Resource Manager (PRM) helps improve your equipment maintenance plans and optimize equipment maintenance costs

Plant equipment maintenance challenges

Complexity of a vast fleet of equipment

Lack of maintenance resources

Depletion of institutional knowledge

Yokogawa’s approach to efficient facility maintenance

Centrally manage and visualize plant equipment data

Achieve cost savings through improved maintenance efficiency

solutions that provide both reliability and efficiency

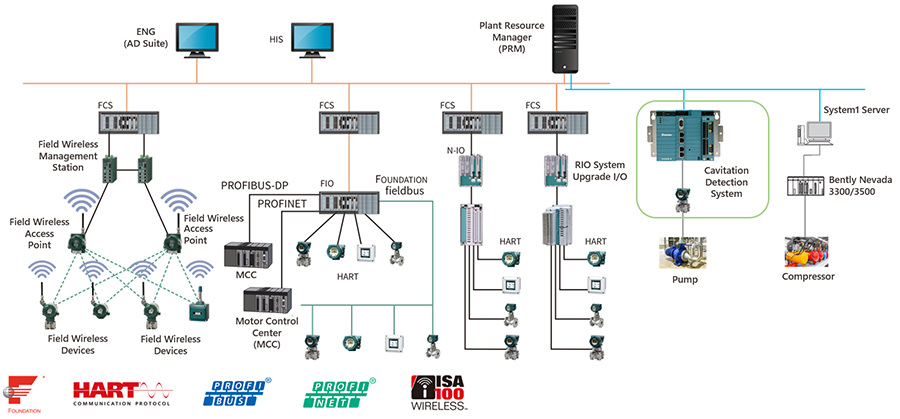

Yokogawa is a trusted provider of systems that keep the plant online, as well as maintenance solutions that allow operations to stay online while achieving reliability and efficiency gains.

Yokogawa streamlines plant management across three levels!

Select which tier to start with based on plant needs

Plant equipment and device malfunctions cause abnormalities and instability to manufacturing workflows, which in turn add to the time it takes to identify the cause of the malfunctions and restore the system. As a result, overall production efficiency goes down. Anticipating equipment malfunctions before they occur and monitoring plant processes for prevention of failures lets you hot-swap equipment with limited impact to operations.

Yokogawa provides solutions across three tiers:

-

Visualize and remotely configure equipment status

-

Device templating allows for efficiently propagating shared parameters across multiple devices

-

Device Type Manager (DTM) and other specialized calibrating tools enable equipment to be brought online quickly

-

More efficient equipment replacement by tracking and comparing parameter logs

-

Reduce man-hours by checking and configuring device parameters remotely

-

-

Monitor equipment and device performance

-

Device patrolling ensures periodic polling of status data for efficient assessment of equipment conditions

-

Versatile diagnostic algorithms allow for measuring valves from multiple vendors

-

Periodic and automatic equipment status reports (field asset KPI reports) visualize conditions and comprehensively assess the health of the plant

-

-

Provide data to enhance maintenance and operations

-

Critical equipment information can be checked immediately not only through DCS but also through comprehensive ICSS (*1) integration for rapid response to problems

-

Loop diagnostics allow for improving control valve performance and maintaining high productivity

-

Work order efficiency is achieved by integrating with higher level systems (ERP/CMMS (*2), etc.)

*1) ICSS : Integrated Control and Safety System (incl. DCS, SIS, and other subsystems)

*2) ERP : Enterprise Resource Planning, CMMS: Computerized Maintenance Management System

-